Foundry Dedusting - Example Crucible Furnace

A frequently encountered melting unit in foundries is the crucible furnace. Due to its simple handling and the possibility of melting different materials in alternating operation, it will continue to maintain its position in melting operations in the future.

WALTER GmbH has equipped numerous such furnaces for gray iron, ductile iron, aluminum, heavy metals and bronze with dust capture and filter systems.

Particular attention must be paid to the requirement that adequate capture of the fine dusts generated occurs in all operating phases such as charging, melting, pouring and sampling.

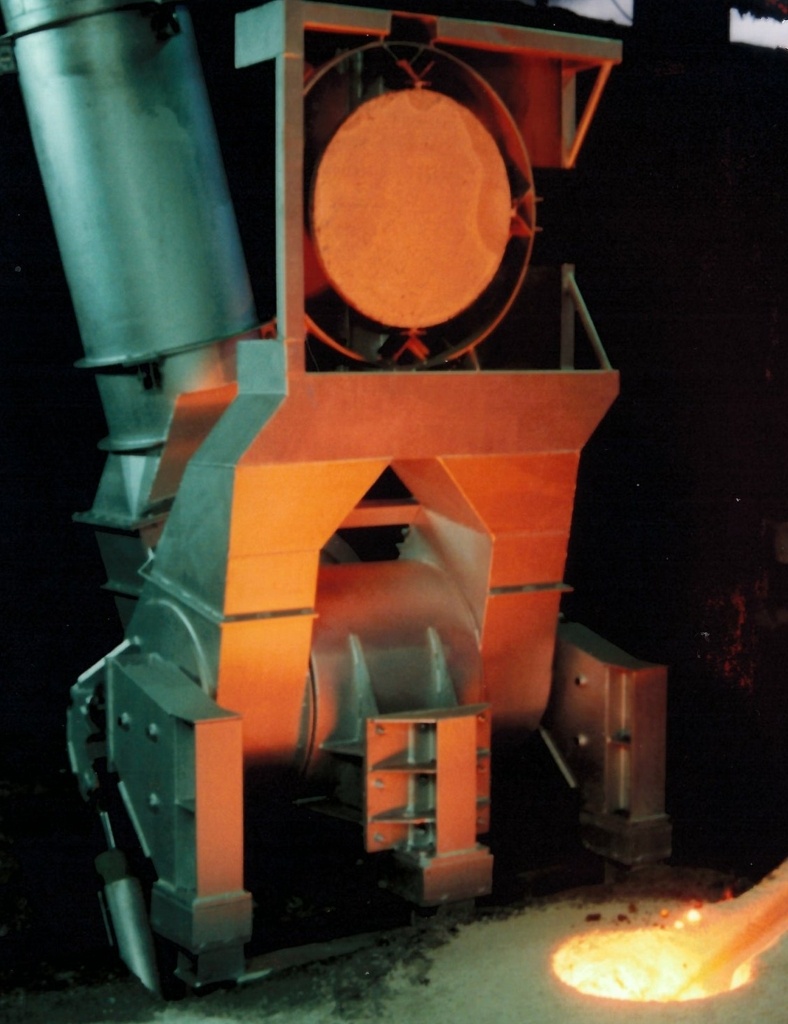

In addition to conventional extraction using stationary or swivel hoods, WALTER GmbH has developed a special hood design that meets all the above conditions.

Permanently installed on the furnace cover and connected to the raw gas line via a telescopic pipe with rotary joints, the hood automatically follows every tilting movement of the furnace up to complete emptying. During charging or dross removal, the furnace hood can be swiveled to any intermediate position, thus freeing the crucible opening.

To optimize extraction and for energy-saving reasons, the extraction volume is automatically adapted to the operating condition depending on furnace and hood position.

When extracting from several furnaces simultaneously and coordinating the work phases with each other, smaller and more economical filter systems can therefore be used.

The WL round bag filters have proven themselves as dust separators for the extremely fine metal oxide dusts. At low filter differential pressures, they work cost-effectively and ensure clean gas dust contents that are clearly below the TA-Luft values.

Would you like to learn more about Foundry Dedusting Crucible Furnace?