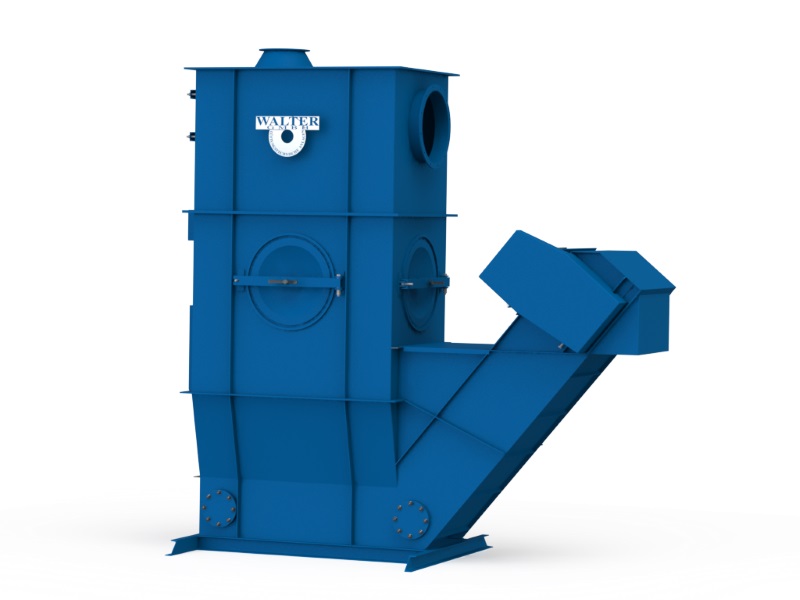

Wet Separators

The NWV series wet separators from WALTER operate according to the Venturi principle.

Wet separators are used for substances that cannot be separated or are difficult to separate in a dry process.

The wet separators can be universally used in almost all industrial sectors.

Applications

- Foundries

- Hardening plants

- Automotive industry

- Aircraft industry

- Food industry

- Grinding shops (steel / aluminum / stainless steel)

- Polishing shops (steel / aluminum / stainless steel)

- Generally for processing fire and explosion-hazardous materials such as aluminum

Operating Principle

The actual wetting zones are designed as short Venturi nozzles. This shape promotes intensive dust wetting. The special separator design enables continued dust wetting even after the nozzle outlet.

After this contact zone, the washing liquid is returned to the water bath by a deflector plate. A downstream droplet separator additionally separates the smallest water droplets and guides the cleaned air to the fan.

The washed out and sedimented dust is drained via a shut-off device on the filter funnel or discharged by a sludge remover, depending on the design.

The water consumption of the wet separator corresponds to the water portion discharged with the sludge and the steam absorption (temperature-dependent) of the air to be cleaned. WALTER wet separators are equipped with electrical and mechanical water level control.

Variants

WALTER wet separators are divided into two device types:

- NWV-T: Discharge via shut-off device and water reservoir

- NWV-S: Discharge via sludge remover

Extraction capacities range from 2,000 m³/h to 40,000 m³/h. For larger air volume flows, the wet separators are installed in parallel.

NWV-S

Would you like to learn more about Wet Separators?