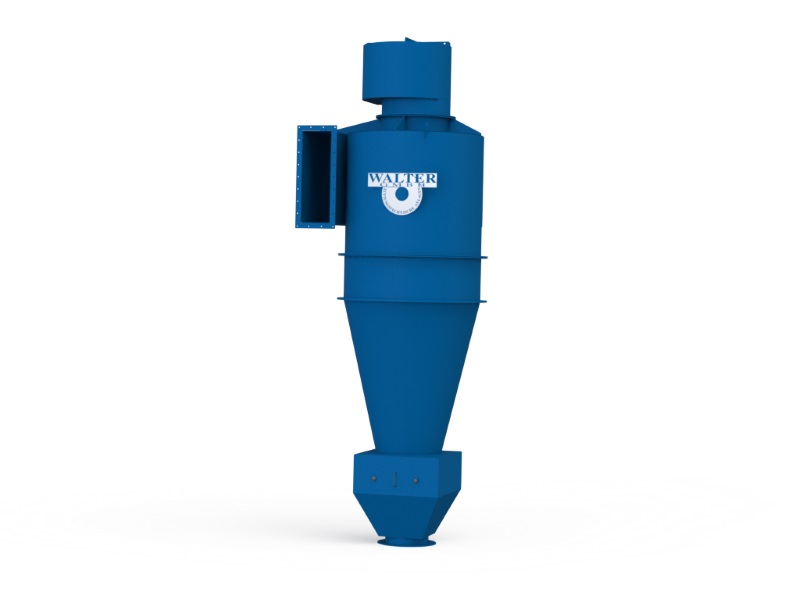

Cyclone Separator

WALTER cyclone separators are installed upstream of the actual filter unit and serve for pre-separation of dry and free-flowing dusts. Medium and coarse dust particles are already separated in advance, protecting the filter media and minimizing their wear. Used as spark pre-separators, they minimize fire risk. They are also suitable for recovery of bulk materials.

Advantages

- Low maintenance

- High operational reliability

- Low space requirement

- High filter system efficiency

- Low flow resistance

- Minimization of fire risk

- Protection against overload and clogging of the main dust collector

Operating Principle

The cyclone separators operate according to the centrifugal principle. The raw gas enters the cylindrical part via the tangential inlet channel. The dust particles are thrown against the outer wall by centrifugal force and separated downward via the funnel-shaped outlet into the settling tank below. The cleaned air leaves the pre-separator at the upper, central exhaust air outlet. Cyclones operate without moving components and are therefore robust and durable.

Optionen

- Wear protection for abrasive dusts

- Rotary valve

Variants

The cyclone separators are available from 1,000 m³/h to 60,000 m³/h.

Cyclone Separators

Would you like to learn more about Cyclone Separators?