Welding Fume Filter for Welding Fume Extraction

Welding fume filters capture and filter the health-hazardous welding fumes generated during welding and soldering of steels (e.g., structural steel, stainless steel, aluminum). The capture of welding fumes is done via capture elements connected to a welding fume filter such as extraction arms, extraction hoods, welding tables or directly on the welding torch. The filtered and particle-free air is discharged outside via a pipeline or returned to the workspace.

Variants

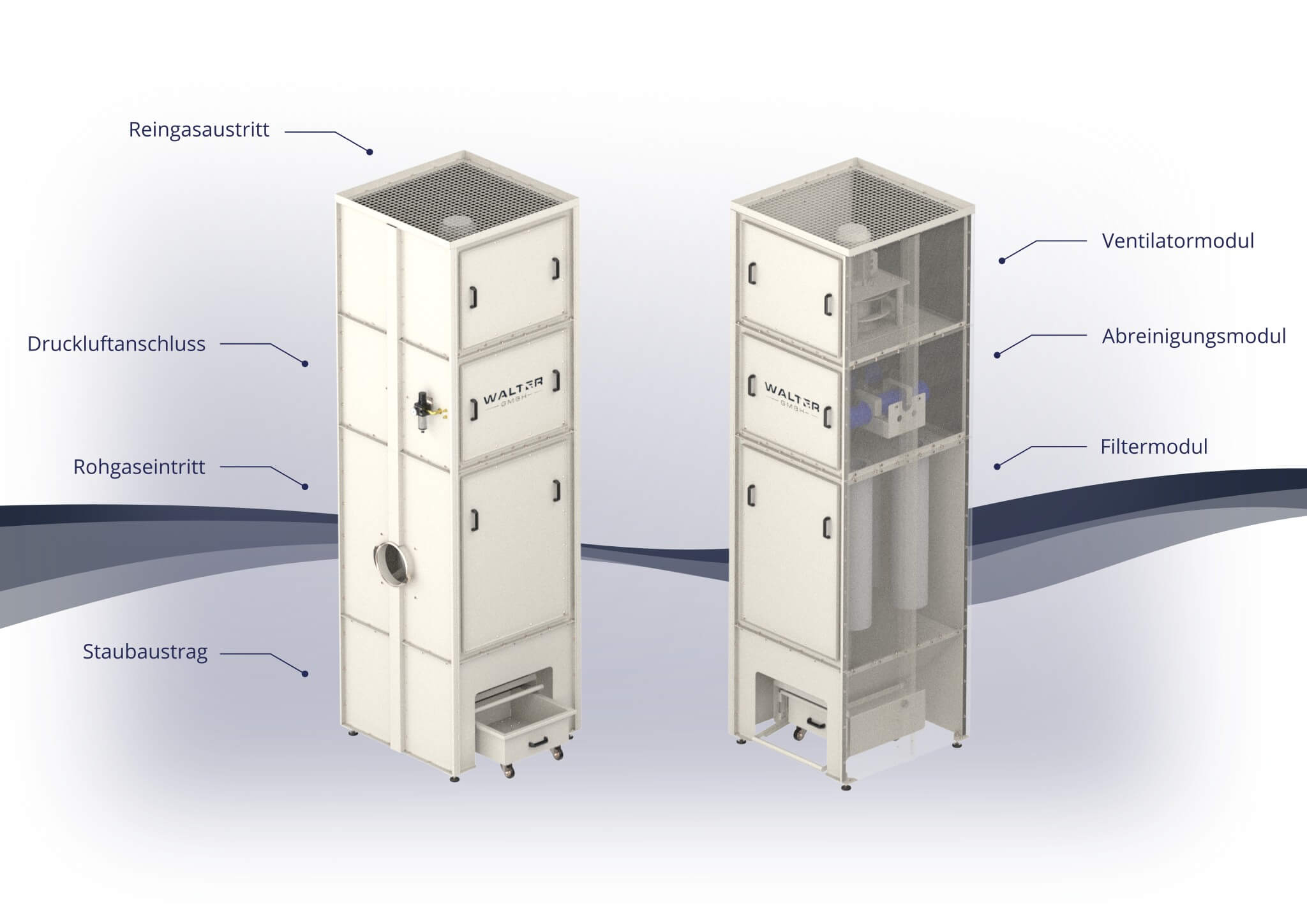

The MPS series welding fume filters are modularly designed and can thus be adapted to the individual needs of welding fume extraction. The extraction devices are available in various versions.

Technical Data WL-MPS

| Version / Module | Filter module with cleaning |

|---|---|

| Volume flow | 3.000 m³/h |

| Connection diameter | DN 250 |

| Width | 1.024 mm |

| Depth | 1.024 mm |

| Height | 1.900 mm |

| Version / Module | Dust discharge |

|---|---|

| Width | 1.024 mm |

| Depth | 1.024 mm |

| Height | 765 mm |

| Height adjustment | 0-60 mm |

| Dust container volume | 50 Ltr. |

| Version / Module | Fan unit |

|---|---|

| Width | 1.024 mm |

| Depth | 1.024 mm |

| Height | 700 mm |

| Version / Module | HEPA module |

|---|---|

| Width | 1.024 mm |

| Depth | 1.024 mm |

| Height | 700 mm |

For higher air capacities, the separators are installed in parallel or manufactured according to customer specifications.

Applications

- Welding

- Soldering

Health hazards and operating costs are minimized through the use of welding fume filters.

Operating Principle

The welding fume filters developed by WALTER work with mechanical separation.

A multi-stage filter system is used.

The air laden with welding fumes flows through the inlet opening into the filter housing where it is strongly decelerated by the volume increase. The welding fumes flow around the cartridges from bottom to top, with welding fume particles being separated on the filter surface.

Through the flexible modular design, both standardized and individually adapted filter sizes can be supplied.

The devices are extremely maintenance-friendly. The installation and removal of filter elements can be carried out simply and quickly through large maintenance doors.

The contamination of the filter cartridges is monitored by the integrated control of the welding fume filter. When necessary, it automatically cleans with compressed air (jet pulse). The separated dust falls into the mobile dust collection container and can thus be easily disposed of.

The fan is mounted on the clean gas side of the device. The welding fume filter comes standard with a sound-insulating hood, so no noise disturbances occur during operation in assembly halls.

Welding Fume Filters

MPS-01

Welding Fume Filters

MPS-01

Dust discharge

Welding Fume Filters

Dust discharge

Welding Fume Filters

Would you like to learn more about Welding Fume Filters?